What is Carvone?

Carvone is a naturally occurring monoterpene with two distinct enantiomers: (R)-carvone and (S)-carvone. Each enantiomer has unique flavors and aromas, with (R)-carvone offering a minty scent and (S)-carvone providing a caraway-like aroma. These characteristics make carvone valuable in various industries, including food, agriculture, and environmental applications.

Carvone analysis service provided by Creative Proteomics is a specialized analytical service designed to quantify and characterize carvone, a monoterpene found in various essential oils such as spearmint and caraway. This service is essential for applications in food and beverage, agriculture, and environmental sectors, where accurate measurement and analysis of carvone concentrations are crucial. Our service includes both qualitative and quantitative analysis, providing detailed insights into the presence and concentration of carvone and its enantiomers.

Carvone Analysis Service by Creative Proteomics

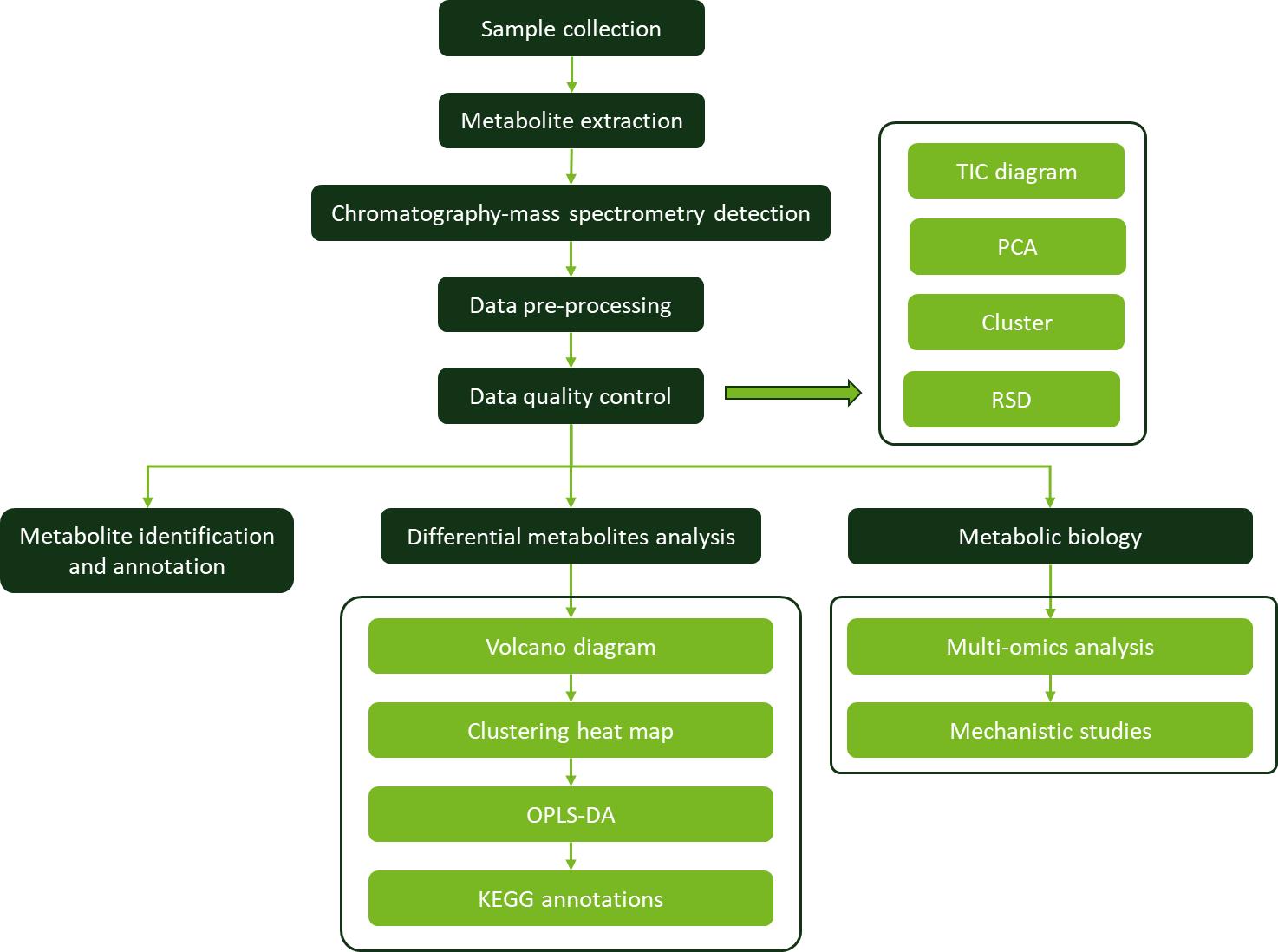

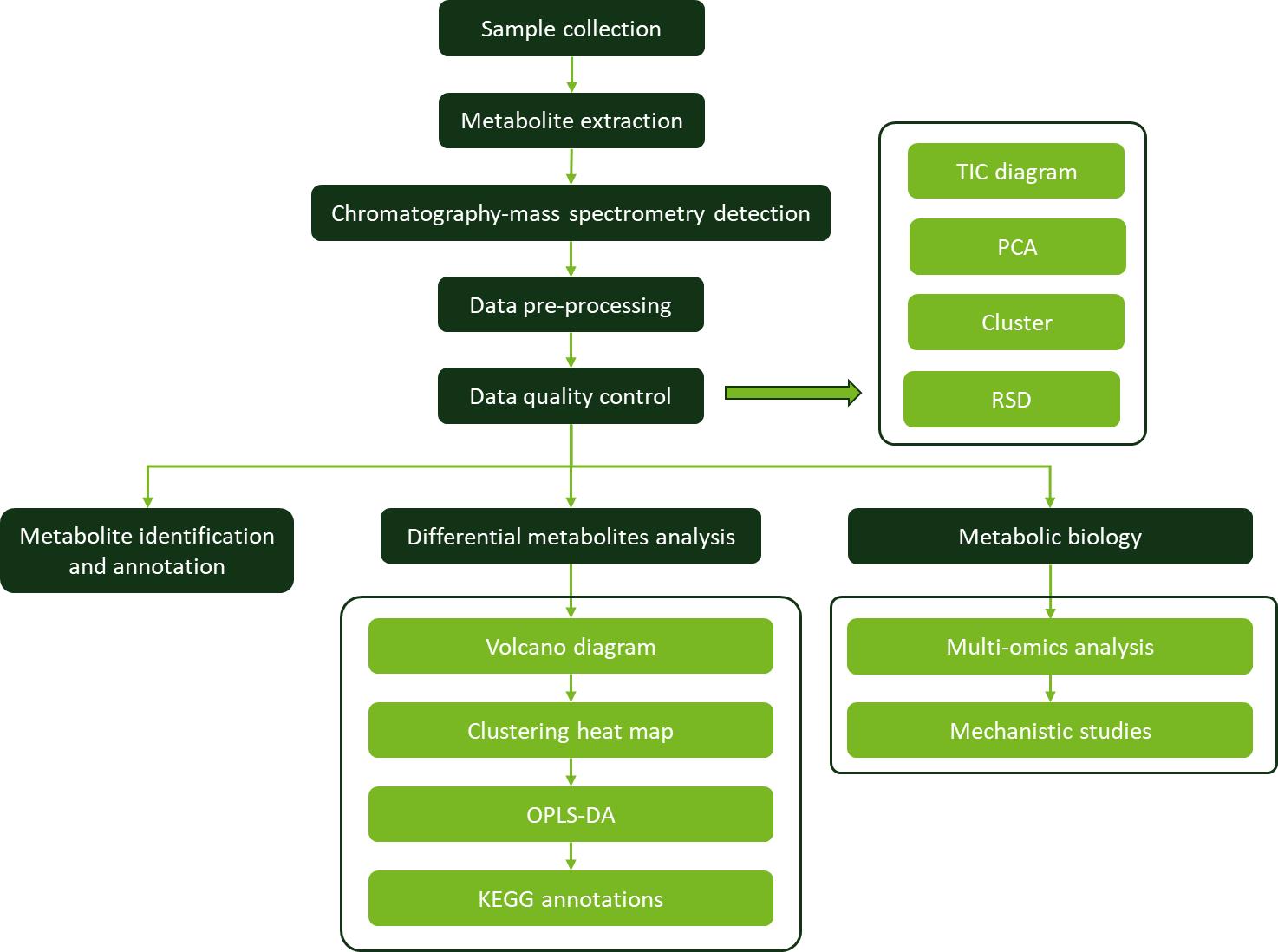

Carvone analysis is a specialized service offered by Creative Proteomics as part of our plant targeted metabolomics analysis, focusing on the identification, quantification, and characterization of carvone in diverse samples. This service is essential for industries that utilize carvone for its flavor, aroma, and functional properties. We provide a comprehensive analysis to meet the specific requirements of our clients, ensuring the accuracy and reliability of results. As follows:

Carvone Quantitative Analysis: Accurate measurement of carvone concentration across various sample types is performed to support research and ensure quality control. This analysis helps in understanding the precise amount of carvone present, essential for both product development and compliance with industry standards.

Carvone Qualitative Analysis: The presence of carvone and its enantiomers is confirmed through sophisticated analytical methods. This ensures that samples meet authenticity requirements and allows for the verification of carvone's identity and purity, crucial for applications in flavor and fragrance industries.

Product Characterization: Comprehensive analysis of carvone's properties within different products is conducted to understand its role and behavior in formulations. This service aids in optimizing product performance and effectiveness by examining how carvone interacts with other components in the product matrix.

Enantiomeric Purity Analysis: The ratio of (R)-carvone to (S)-carvone is determined to evaluate the enantiomeric purity of carvone. This analysis is vital for applications where the specific enantiomer has distinct properties or effects, ensuring the integrity and quality of carvone used in various applications.

Trace Analysis: Detection and quantification of extremely low levels of carvone in complex samples are performed with high sensitivity. This service is essential for applications requiring precise measurement of carvone at trace levels.

Techniques and Instrumentation for Carvone Analysis

Gas Chromatography (GC): Separates and quantifies volatile carvone.

Instrumentation: Utilizes advanced GC systems with flame ionization detectors (FID) or mass spectrometry (MS) to achieve high sensitivity and accurate results.

High-Performance Liquid Chromatography (HPLC): Separates and quantifies carvone in complex matrices.

Instrumentation: Employs HPLC systems with UV detectors or MS for precise detection and quantification of carvone.

Mass Spectrometry (MS): Provides detailed molecular information and quantification of carvone.

Instrumentation: Includes high-resolution mass spectrometers for accurate molecular identification.

Applications of Carvone Analysis

Food and Beverages: Carvone analysis ensures the correct concentration of carvone in flavorings and essential oils for products like chewing gum and candies. It also supports flavor enhancement in new food and beverage formulations.

Agriculture: Carvone analysis helps monitor its levels in crop protection applications, such as antisprouting agents for potatoes. It also ensures carvone concentrations in agricultural products meet regulatory standards.

Environmental: In environmental monitoring, carvone analysis assesses its impact on soil and water quality and evaluates its effects on ecosystems and non-target organisms.

Pharmaceutical and Cosmetic Industries: Carvone analysis verifies purity and concentration in pharmaceutical and cosmetic products, ensuring quality and supporting the development of new formulations.

Sample Requirements for Carvone Analysis

| Sample Types |

Sample Size |

Biological Repeat |

| Liquid Samples |

Essential oils, beverages, or extracts |

≥1 mL |

3-6 |

| Solid Samples |

Powders, granules, or solid extracts |

≥1 g |

| Complex Samples |

Mixed or complex matrices |

≥2 mL or ≥2 g |

Q1: What methods are employed to assess the ratio of (R)-carvone to (S)-carvone?

A1: Enantiomeric purity is determined using optical rotation and chiral chromatography. These methods measure the ratio of (R)-carvone to (S)-carvone, ensuring that the carvone isomer proportions meet the required purity specifications for various applications.

Q2: What measures are taken during stability testing to simulate real-world conditions and ensure the longevity of carvone in products?

A2: Stability testing involves exposing carvone to various conditions such as temperature, light, and humidity to simulate real-world storage environments. This testing helps determine how carvone maintains its integrity over time, ensuring product longevity and reliability.

Q3: Are there any special sample preparation or handling instructions to ensure the integrity of the carvone analysis results?

A3: Yes, samples should be collected in waterproof and inert vials to prevent contamination. Proper handling includes minimizing exposure to light and temperature extremes to maintain sample integrity before analysis.

Case. Increased carvone production in Escherichia coli by balancing limonene conversion enzyme expression via targeted quantification concatamer proteome analysis

Background:

The natural production of (−)-carvone from spearmint faces sustainability issues. This study seeks to improve biotechnological production of (−)-carvone by enhancing enzyme expression in E. coli and using advanced protein quantification techniques to overcome previous low yield challenges.

Samples:

Strains: Recombinant E. coli strains BL21(DE3) were used as hosts for protein expression and biocatalysis.

Substrates: (−)-limonene was used as the starting substrate for the biocatalysis process.

Technical methods procedure:

Plasmid Construction: The QconCAT method was used to generate standard peptides for quantification.

Strain Development: Proteins were purified, and the strains' biocatalytic activities were evaluated.

Protein Quantification: Enzyme levels were quantified using the QconCAT method, involving the creation of QconCAT proteins, their digestion, and LC-MS/MS analysis.

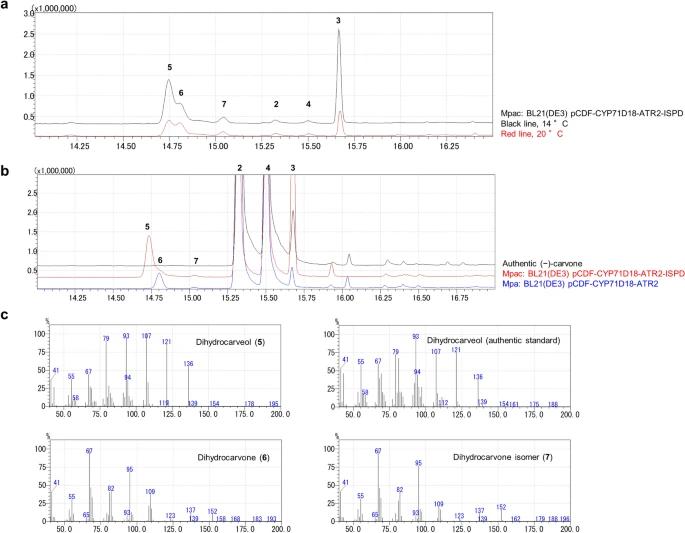

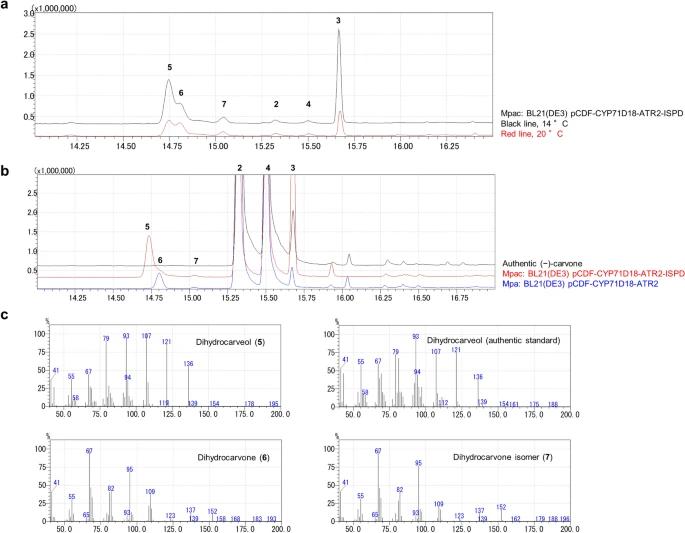

Analytical Methods: Gas chromatography and mass spectrometry (GC-MS) analyzed the biocatalysis products and by-products.

Results:

Optimizing the P450 to CDH ratio led to a 15-fold increase in (−)-carvone production.

By-products like dihydrocarveol and dihydrocarvone were reduced by lowering CDH expression.

The QconCAT method effectively determined the optimal enzyme balance, demonstrating its value in industrial strain development.

Carvone production from limonene using a recombinant Escherichia coli strain co-expressing P450, CPR, and CDH, and identification of by-product compounds. Cytochrome P450 limonene-6-hydroxylase gene from spearmint (CYP71D18), cytochrome P450 reductase (CPR) gene from Arabidopsis thaliana (ATR2) and carveol dehydrogenase (CDH) gene from peppermint (ISPD) were used as P450, CPR, and CDH, respectively.

Carvone production from limonene using a recombinant Escherichia coli strain co-expressing P450, CPR, and CDH, and identification of by-product compounds. Cytochrome P450 limonene-6-hydroxylase gene from spearmint (CYP71D18), cytochrome P450 reductase (CPR) gene from Arabidopsis thaliana (ATR2) and carveol dehydrogenase (CDH) gene from peppermint (ISPD) were used as P450, CPR, and CDH, respectively.

Reference

- Yoshida, E. et al. (2021). Increased carvone production in Escherichia coli by balancing limonene conversion enzyme expression via targeted quantification concatamer proteome analysis. Scientific Reports, 11(1), 22126.

Carvone production from limonene using a recombinant Escherichia coli strain co-expressing P450, CPR, and CDH, and identification of by-product compounds. Cytochrome P450 limonene-6-hydroxylase gene from spearmint (CYP71D18), cytochrome P450 reductase (CPR) gene from Arabidopsis thaliana (ATR2) and carveol dehydrogenase (CDH) gene from peppermint (ISPD) were used as P450, CPR, and CDH, respectively.

Carvone production from limonene using a recombinant Escherichia coli strain co-expressing P450, CPR, and CDH, and identification of by-product compounds. Cytochrome P450 limonene-6-hydroxylase gene from spearmint (CYP71D18), cytochrome P450 reductase (CPR) gene from Arabidopsis thaliana (ATR2) and carveol dehydrogenase (CDH) gene from peppermint (ISPD) were used as P450, CPR, and CDH, respectively.