Metalworking Fluids Analysis Service

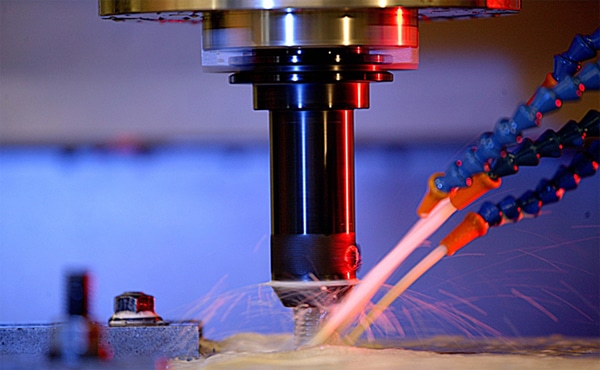

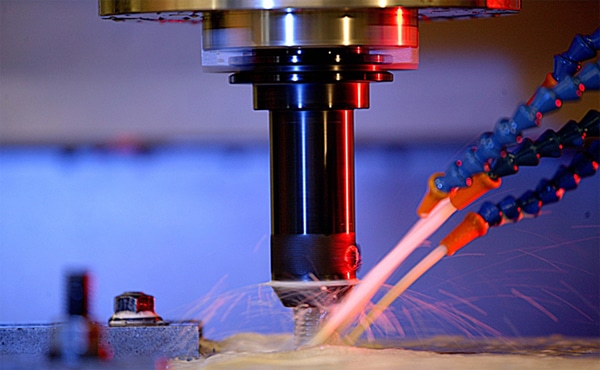

Metalworking fluids (MWFs) are a range of oils or liquids being used to cool or lubricate when metals are being machined, ground and milled. By reducing the friction and carrying away debris such as swarf and fine metal particles, MWFs protect the work piece and prolong the life of the tool. Metalworking Fluids (MWF) are segregated into four main categories: neat oils (straight oils), soluble oils (emulsifiable oils), semi-synthetic fluids and synthetic fluids.

The properties and composition of MWFs can not only affect their efficiency of cooling and lubrication, but also have many health concerns such as contact dermatitis or certain cancers. Tests and analysis of MWFs are necessary for their different application and assessing their health risks.

Creative Proteomics offers analysis service for the following MWFs or products related to MWFs.

| • | Metalwork fluid products

Cutting fluids, grinding fluids, polishing agent, quenching oil, slushing oil, lubricants, gear oil, hydraulic fluid, vacuum pump oil, thermal oil, transformer oil, punching oil, chain oil, rolling oil… |

| • | Metalworking fluid raw materials

Mineral oils (e.g. naphthenic oil), bio-based oils (vegetable oils and esters), synthetic oils (e.g. poly-alpha-olefin), recycled oils (re-refined oils) |

| • | Metalworking fluid additives

Sulphurized or chlorinated compounds, corrosion inhibitors, extreme pressure additives, anti-mist agents, emulsifiers, alkanolamines, biocides, stabilizers, dispersants, colourants, dyes, odorants, fragrances |

Analysis and test services available for MWFs at Creative Proteomics include:

• Compositional Analysis

• Deformulation (reverse engineering)

• Identification of Unknown Material

• Fault Detection and Diagnosis in Industrial System

• Product and Process Development

• Contract R & D

Related Services